Northern Steel Industries is launching its automated fertilizer cardlock system today. With fertilizer companies throughout the West converging on Tisdale, this is an important event in the industry. The dealers will have an opportunity to see this unique system in action and find out how it can work for them to provide better service to the farmer and in turn will produce better results and accuracy for the

agricultural

situations that

agricultural

situations that include so many variables.

These pictures were taken at 10:30 this morning as preparations were underway to handle the visitors and give them a first hand look at technology that does not exist anywhere else.

Northern Steel Industries patented system combines computer technology, modern telecommunications with solid durable hardware. Here is how it works.

Liquid fertilizers are bulky

and require

considerable transportation of the product from

and require

considerable transportation of the product from the supplier to the field. This means that reducing the haul -ing distance improves convenience and allows the farmer the accuracy that the use of this product affords. This system involves completely automated operations that can run twenty-four hours a day, close to the customer and controlled and monitored by the dealer, who in turn, can spot many such systems in his service area.

The advantage of liquid fertilizer is that without additional moisture, the nutrients are available immediately to the growing plant and this new system allows the blending of the product to suit the needs of a particular field and crop, or growing situation. The farmer takes the results of his soil samples to the fertilizer supplier, who issues a customer card and encodes the various farm fields in which he will be applying the product. Essentially, he can tailor make the components, nitrogen, phosphates, potassium and potash field by field.

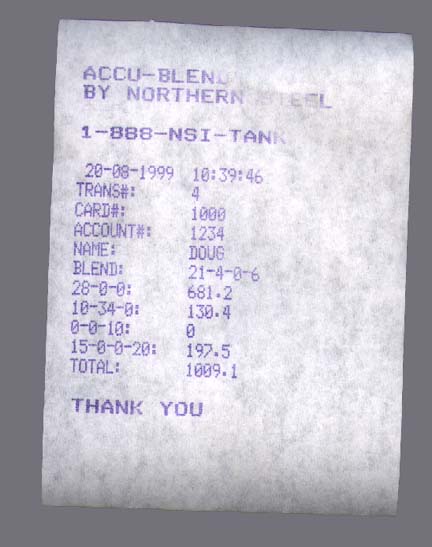

To take delivery, the farmer drives his truck to the ACCU BLEND station with is four tanks of product, climbs up to the delivery dock where he swipes his card. He punches in his pin number and the field he is working on and a computer system takes over to give him what he needs and the volume he can handle. As you can see in the picture at right, Doug, of Northern Steel is holding the delivery switch with which he can stop the loading process instantly and control the truck's tank loading from the delivery dock.

When the customer has filled his tank, the transaction is billed to his account and the card system on the dock prints out his receipt, which not only sets out the time and date,

but

also shows his account,

but

also shows his account,the blend of fertilizer he has in his tank, and the total volume that he has received. The whole process is controlled by a computer system that handles the turning on and off of pumps and valves to mix the exact combination needed.

On the dealer end of things a dedicated telephone line reports the sale and updates inventory in the depot. This means the dealer can maintain a presence at that remote location and if problems arise regulate the access of the customer. In addition, the depot has a printer to produce a simple hard copy of the delivery, this way, backing up the electronic computer record of the transaction.

The computer and its software are at the heart of this system and they in turn can be serviced by both the dealer and ACCU BLEND remotely using the telephone link.

Though the details of the operation are interesting and important to the dealers the concept itself is the main event. Liquid fertilizer is better and farmers are ever in need of means to do their work efficiently, over fertilizing and applied the wrong product, or a general product that does not specifically handle the needs

of a

particular field, is wasteful, so that this ACCU BLEND

of a

particular field, is wasteful, so that this ACCU BLEND system makes accurate fertilization available to the farmer without increasing the labour component to the dealer, which would make manned depots to costly to operate. Northern Steel Industries has come up with an idea that not only makes sense, but is a major break through in the whole agricultural picture and with commodity prices remaining low, efficient spending on input cost will determine which farm operations remain viable and which do not.

The mechanical portions of this operation are interesting. The computer is housed in the cabinet above the printer seen on the right and the blending valves and pumps are seen below. The government's weights and measures regulations determined that the sale be metered in mass volume and insure that the system give the customer accurate amounts. The whole system is an integrated system of the mechanical hardware, the computerised system and clever steel construction, that allows this operation to be located any where there is electrical power and a telephone line.

Over thirty representatives of various companies involved in agricultural marketing were on hand for the luncheon and presentations on this revolutionary new product. The picture at right is the scene right after lunch at around 12:45 today as the afternoon proceedings were about to begin.