|

| FTLComm - Tisdale - August 25, 2000 |

Northern Steel Industries has developed what may well be a revolutionary way of mixing and providing fertilizer to agriculture. The system first introduced last summer has drawn interest and enthusiasm from fertilizer distributors and has the potential for being the standard means for selling liquid products. Saskatchewan Wheat Pool's Harvest Valley agricultural products distributor has installed an Auto-Blend system and are enthusiastic after having had it in operation since spring. They have found that about fifteen farmers have made use of the automated system |

on their

own but for Harvest on their

own but for HarvestValley the main benefit has been the accuracy and ease for their own staff when delivering the product using their trucks. Since the Harvest Valley delivery trucks are all bottom loading this installation did not include the elevated loading dock that is a feature of the convention installation. Since this was not a new installation as Harvest Valley had been handling liquid product before, they adapted their equipment to the new Auto Blend system so their old weighing and manual valve system can still be identified, but as the manager explained to me, this system is just so superior that it cuts time, improves accuracy and gives the farmer the exact product he needs for the application at hand. The automated card reader is seen at right and the hand held loading switch is hanging on the wall beside the safety cut off switch. Liquid fertilizers are difficult chemicals to handle and extremely corrosive on plumbing. This explains the high quality stainless steel automated flow meter system that is the heart of the Auto Blend system. |

When first introduced Northern Steel called this system AccuBlend but it turned out that someone already owned that name and the system now is patented under the name Auto Blend. Though the accuracy of mixing the various products is a main feature of the system, the real benefit to the customer and the retailer is the simple automated process of handling the complex combinations of various liquid blends to produce exactly the fertilizer needed. |

To get that automation and accuracy it requires a computer and its software which can be seen here attending to business. Computer technology in this kind of situation is ideal since this system is monitored in the managers office and can be controlled , customers added and altered directly from the main business office, thus allowing the actual system to function without the need of someone coming over to the site and having to deal with the various details of the operation. The manager for Harvest Valley said that their experience with the system really has proven the merits of Auto Blend and he believes that the remarkable quality and specific nature |

of selling

the farmer the proper mixture will see this system of selling

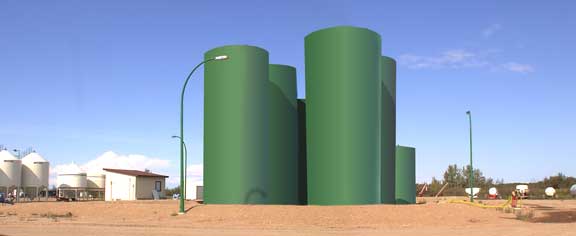

the farmer the proper mixture will see this systemand the use of liquid fertilizer expand even more when farm economic situations will become a little less tight. Harvest Valley sells seed, anhydrous ammonia and liquid fertilizer at is installation South of Tisdale. They have two field spraying rigs that are on the go constantly as well as two other fertilizer application systems which provide farmers with custom application. Anhydrous ammonia is widely used with continuous agriculture and cereal grains as it is applied in a gaseous state in the fall and spring. However, liquid ammonia products are becoming increasingly popular largely because of the Auto Blend system which makes the product easy and much safer to handle. Liquid ammonia is only 28% compared with the full strength gas application, but because it is so much easier and safer to use, many are predicting that it will become just as popular as banding with gas. The control panel for the Auto Blend system is seen in the picture on the right and includes a uninterrupted power supply to handle any glitches in SaskPower thus protecting the computer and keeping the system operational. The installation of a liquid fertilizer system is extensive. Harvest Valley had to create the dike containment system with a thick plastic liner then covered with pea gravel to insure the safety of handling these chemicals that can get out of the tanks and would contaminate the ground water. The picture below illustrates the extent of this installation with its system of tanks and on the right hand side of the picture, the input lines for refilling the various liquid fertilizer tanks. |

|

The summer staff at Harvest Valley is over thirty people involved in all the aspects of servicing the agricultural needs of this expanded community. With the extensive developments in modern agriculture Harvest Valley is just one of several highly specialised operations that provide fertilizer, spraying and chemical supply. |